Optimal Timing for Vapor Barrier Installation

Vapor barrier installations are most effective when performed during specific weather conditions and construction phases. Optimal timing ensures proper adhesion, minimal moisture interference, and long-term durability of the barrier. The ideal period typically involves dry, mild weather to prevent moisture infiltration and allow for thorough installation.

Late spring and early fall often provide the best conditions due to moderate temperatures and low humidity, facilitating proper adhesion and curing.

Heavy rain, snow, or extreme temperatures can compromise vapor barrier effectiveness and installation quality.

Installing vapor barriers during foundation or framing stages minimizes disruption and ensures proper integration with other building components.

Ensure the surface is dry and clean before installation to maximize adhesion and performance.

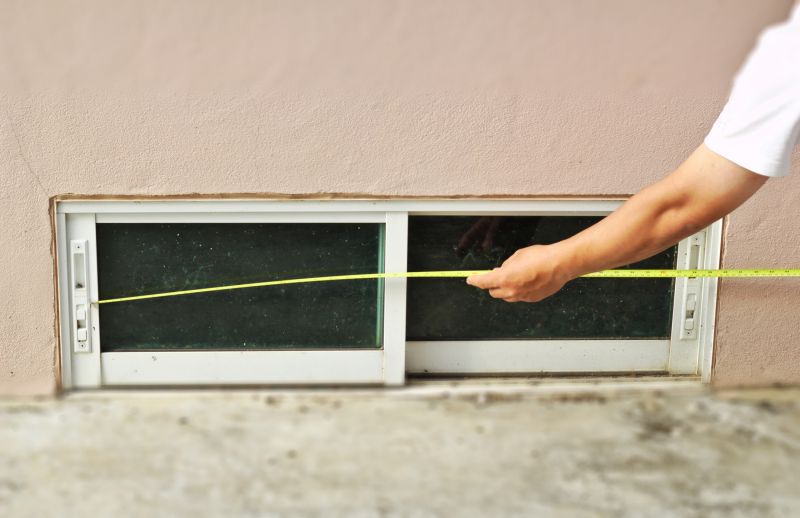

Ways to make Vapor Barrier Installations work in tight or awkward layouts.

Popular materials for Vapor Barrier Installations and why they hold up over time.

Simple add-ons that improve Vapor Barrier Installations without blowing the budget.

High-end options that actually feel worth it for Vapor Barrier Installations.

Finishes and colors that play nicely with Vapor Barrier Installations.

Little measurements that prevent headaches on Vapor Barrier Installations day.

A 60-second routine that keeps Vapor Barrier Installations looking new.

A frequent mistake in Vapor Barrier Installations and how to dodge it.

| Aspect | Details |

|---|---|

| Best Seasons | Late spring and early fall |

| Weather Conditions to Avoid | Rain, snow, extreme heat or cold |

| Ideal Installation Time | During foundation or framing stages |

| Preparation Needed | Dry and clean surface |

| Impact of Timing | Enhances durability and performance |

Vapor barrier installations are crucial for preventing moisture intrusion in building structures, particularly in basements, crawl spaces, and flooring systems. Proper installation reduces the risk of mold growth, wood rot, and structural issues caused by excess moisture. Statistics show that well-installed vapor barriers can decrease indoor humidity levels by up to 50%, significantly improving building longevity and indoor air quality.

Selecting the right time for vapor barrier installation can influence its effectiveness and lifespan. Weather conditions, construction phase, and surface readiness are key factors. Installing during dry, mild weather ensures optimal adhesion and reduces the likelihood of future moisture-related problems. Proper timing also minimizes disruptions and ensures compliance with building standards.

Small tweaks to make Vapor Barrier Installations safer and easier to use.

Lower-waste or water-saving choices for Vapor Barrier Installations.

The short, realistic tool list for quality Vapor Barrier Installations.

Rough timing from prep to clean-up for Vapor Barrier Installations.

Quick checks and paperwork to keep after Vapor Barrier Installations.

Examples that show the impact a good Vapor Barrier Installations can make.

Ways to make Vapor Barrier Installations work in tight or awkward layouts.

Ways to make Vapor Barrier Installations work in tight or awkward layouts.

Interested in vapor barrier installations? Filling out the contact form can provide more information and help schedule an assessment to determine the best timing for specific project needs.